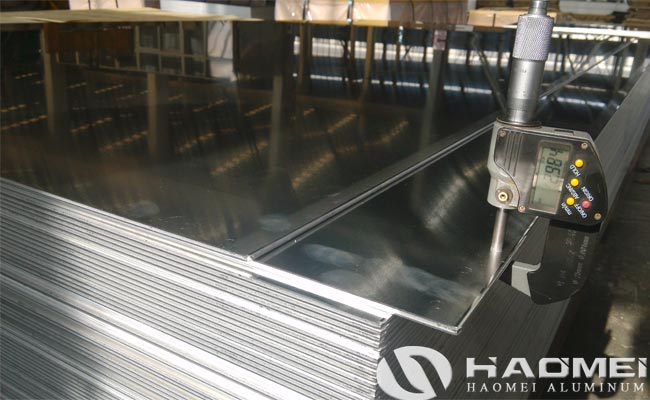

Thick aluminium sheet supplier mainly produce aluminum sheet 1060, 2024, 3003, 5052, 5083, 6061, 6082, 7075 with thickness over 8mm. In the industry, aluminum sheets are usually classified according to their thickness. Thin aluminum sheets are usually less than 1mm thick, plain aluminum sheets are between 1mm and 8mm thick, and thick aluminum sheets are more than 8mm thick. This classification is mainly based on the processing method, for example, aluminum sheets up to 8mm can be processed by choosing cold-rolling equipment, while aluminum sheets more than 8mm have to be manufactured by using hot-rolling equipment. Thick aluminum sheet is widely used in many industries such as construction, furniture, automotive, aviation, electronics and so on.

The production process of thick aluminium sheet supplier mainly includes the following steps:

Smelting:

Aluminum ingots after melting into liquid aluminum, at this time you can add some alloying elements to further improve the mechanical properties of aluminum sheet.

Casting:

Molten aluminum liquid through a special casting process, casting aluminum slab billet.

Rolling:

Aluminum slabs are rough rolled in a heated state, and the thickness of the aluminum slab is initially pressed. After rough rolling, the aluminum slab needs to be heated continuously and rough rolled again until it reaches the ideal size and thickness. Afterwards, finish rolling is carried out, and after the fine rolling process, the aluminum sheet becomes the aluminum sheet and coil material of specific specifications and dimensions.

Annealing:

Annealing is an indispensable step in the production of aluminum sheets, which gives them good mechanical and physical properties. The annealing process eliminates the internal stresses of the sheet by applying controlled heating and cooling treatments to the aluminum sheet, thereby increasing the bending capacity and plasticity of the sheet, and improving its workability and corrosion resistance.

As for the use of thick aluminum sheet, it is widely used in many fields:

Processing materials for various pressure vessels: such as storage tanks, oil drums, reactors, etc. These vessels require high strength and stiffness.

Aviation field: used as materials for processing thin-walled parts such as airplane fuel tanks and fuel pipes, which have complex shapes and harsh working conditions.

Shipbuilding: used as hulls, keels and superstructures, etc. The shipbuilding industry requires high strength and corrosion resistance of the materials used.

Chemical equipment: used to make a variety of structural parts of the substrate, chemical equipment, the working conditions are harsh and the medium has chemical toxicity or corrosive.

In general, thick aluminium sheet supplier process aluminum sheet with high quality and it plays an important role in industrial production due to its excellent performance and wide range of applications. The specific choice of alloy and thickness of aluminum sheet needs to be based on the actual application scenarios and needs.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form